Sourcebynet was invited to present at the recent prestige FSC Asia Pacific Business Forum 2022

FSC has been dedicated to promoting responsible forest management worldwide and upholding the highest standards in responsible forestry at best. FSC believe that transforming the market into responsible sourcing is an effective way to halt deforestation and the new norm of doing business.

After a three-year hiatus, the most anticipated “FSC Asia Pacific Business Forum 2022” networking and leadership occasion was held in central Bangkok, Thailand between 28 and 29 November 2022. Sourcebynet’s Product Sustainability Manager, Benjamin Peadon was invited to the event and given the opportunity to present on how there is an increasing demand for sustainable wooden furniture.

Sourcebynet’s Product Sustainability Manager, Benjamin Peadon and FSC Vietnam Country Director, Ms. Que Anh

The FSC Asia Pacific Business Forum 2022 was a keystone business event that served several purposes:

- An exclusive networking event where FSC-certified suppliers in Asia Pacific can have dialogue with international buyers, retailers and FSC promotional license holders

- It helped brands and retailers build strong and sustainable forest product value chains, as many representatives from plantations were present

- The official launch event for the FSC x UN-REDD Sustainable Tropical Timber Trade Network and Information Hub

The event kicked off early morning of 28 November with FSC Chief Markets Officer, Jeremy Harrison welcoming all attendees to the forum. Jeremy highlighted the key objectives for the event, as well giving a current market insight of what FSC had seen over 2022. The primary focus of the event was around the current rubberwood supply chain of Thailand. Thailand is a major exporter of rubberwood, shipping over 65% of its rubberwood production abroad. Thai rubberwood is competitive thanks to its quality and price, especially when compared with other types of woods. Rubberwood is a hardwood, and as such easy to use; it is also relatively cheap compared to similar woods.

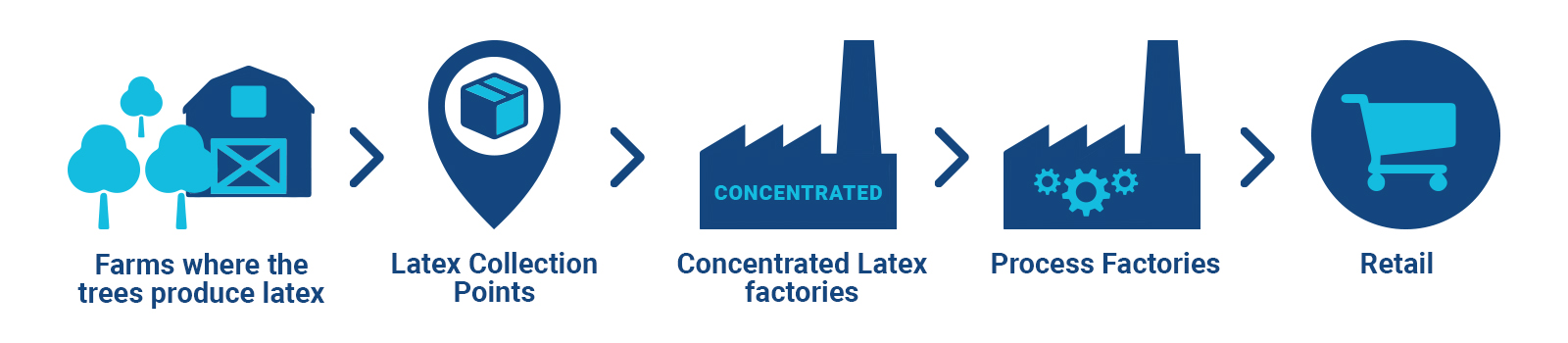

As well as being used for furniture, rubber trees produce natural extracts which are processed and used for rubber products such as gloves, tires, car interiors and apparel. Within Thailand, FSC have overseen the world’s first fully integrated Rubber Company to certify FSC for the whole of our LATEX supply chain from up-stream to down-stream. This includes the farms where the trees produce latex, the latex collection points, the concentrated Latex factories, the process factories and finally to retail.

Throughout the day, there were several keynote speeches from industry-leading companies that work directly with FSC. The companies ranged from harvesting rubber wood, all the way through to producing products that use rubber as a primary material.

The event played host to a range of discussion forums, where a select panel were placed together to tackle ongoing issues within the rubber industry. One of the key highlights was a panel that consisted of a rubber plantation owner, and the respective marketing heads for BMW and Pirelli discussing the lowering prices of rubber wood. The respective marketing heads for BMW and Pirelli were challenged on how multi-billion-dollar companies continue to squeeze the farmers on price for every drop. The response was a little subdued, with both marketing heads unable to present a solution.

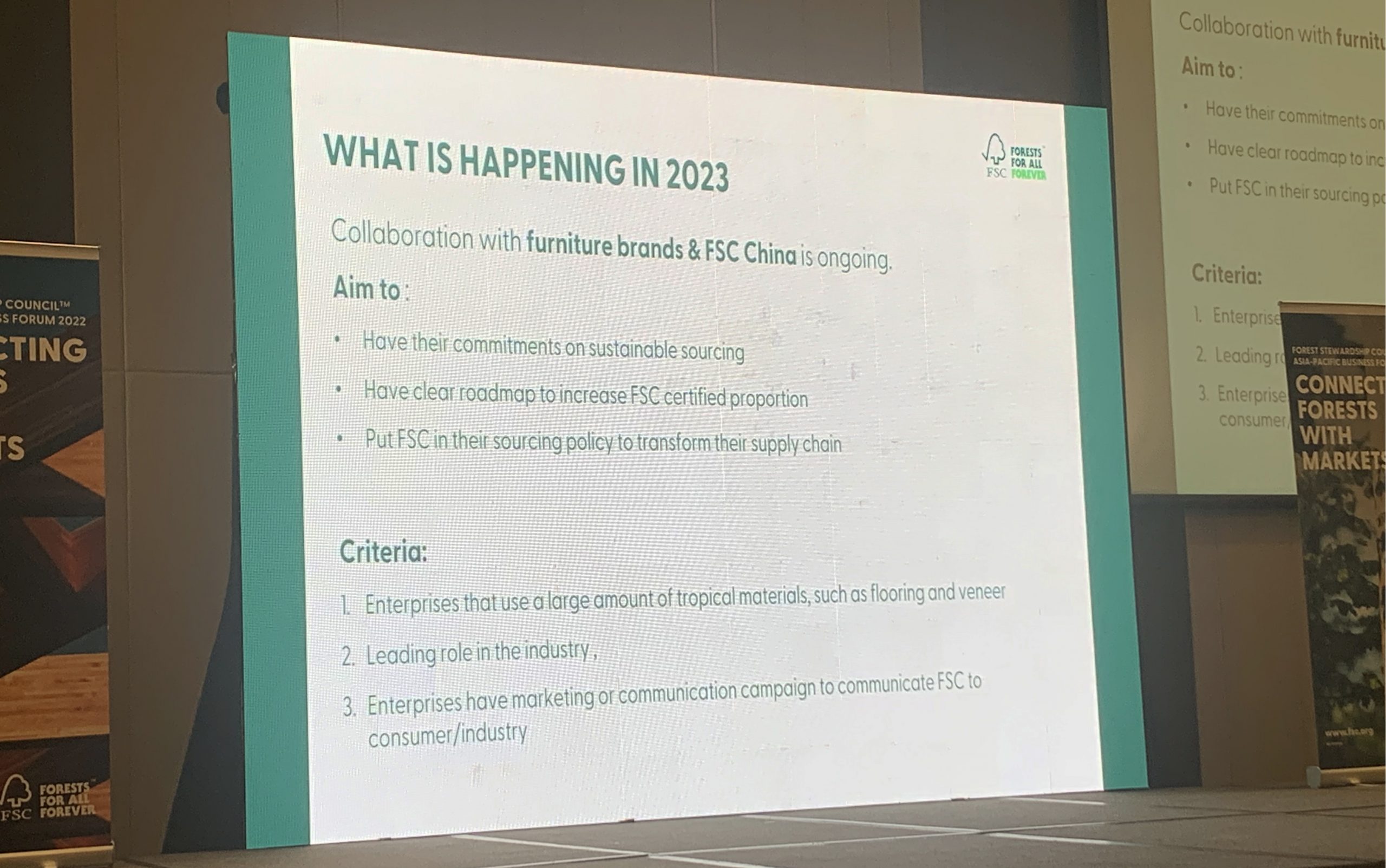

Another key highlight of the day was the presentation from FSC China. It was positive to hear that there are key developments taking place between FSC China and the Chinese government.

Article 65 has been introduced by the Chinese government to try to combat the production, purchase, and transportation of illegally felled timber.

Sourcebynet’s Product Sustainability Manager presented how there is “An Increasing Demand of Sustainable Wooden Furniture”. The presentation was focused on Sourcebynet’s journey with FSC, the rise of the sustainable consumer and how there is an increasing change among retailers to only offer FSC certified products. Given that Sourcebynet were the only FSC member associated directly with furniture design and retail, the presentation was well received, with several questions asked.

Several brands highlighted some of the amazing products that are made using FSC certified materials. These included:

- The first FSC certified car tire from Pirelli, constructed using rubber from FSC certified plantations in Thailand

- FSC certified rubber used for the sole of Allbirds footwear

- Latex surgical gloves from Sri Trang Production that were FSC certified

- Several interior components for the BMW X5 made from FSC certified rubber

- Reusable packaging from computer manufacturer Asus, that prolongs the use of the box by enabling the user to create a laptop stand

Reusable packaging from Asus and latex surgical gloves from Sri Trang Production

The attendees of the APAC forum headed three hours Southeast of Bangkok to the region of Rayong in the early morning of 29 November. Rayong is notorious for being one of the leading locations for growing and harvesting rubber wood and latex.

The attendees visited several rubber plantations that were both FSC and Non-FSC certified.

The plantations visited were using the traditional way of collecting rubber, known as tapping. Tapping is performed by the tree being shed of its bark and a stream being set-up for the rubber to run down the tree and be collected in a bowl.

One third of the tree has its bark shredded and tapped. This process does not harm the tree, with the bark growing back continuously.

Tapping at the plantations happens 250 days a year, with the plantations harvesting the trees after 25 years. The wood is then commonly used within the furniture industry.

Left: Shaving the bark from the tree in the initial stage, preparing the tree to be tapped at the end. Right: Collecting the natural rubber at the end of the tapping process

Following the visit to the plantations, the attendees to a trip to a local sawmill that were working to cut and prepare the rubber wood for various industries.

Rubberwood is a fined-grained and easily worked timber that furniture and flooring producers are willing to pay a premium for.

It was a very rewarding to see the full process of rubber and rubberwood being harvested, as well as understanding more about the challenges within the industry.

To conclude, the key takeaways from the event:

- FSC and Thai Government seem to be working hand in hand – giving other countries within the region hope

- Rubber wood is still a valuable material for producing furniture, with pricing fiercely competitive

- Still not enough support for the farmers and harvesters of rubber wood plantations

- FSC is supporting but is limited to what they can do

- Other countries still challenged for certifying FSC, especially within the rubber wood industry